autoclaves for fermenter sterilization|autoclave step by procedure : online sales Heat sterilization is the most effective method of sterilization, where the elimination of microbes is achieved by the destruction of cell constituents and enzymes. It is done by two methods: Moist Heat Sterilization: It is one of the best methods of sterilization. Moist heat sterilization is done with the help of an instrument called an autoclave. Resultado da Hit the like botton

{plog:ftitle_list}

webKinechan FOTOS, VIDEOS E GIFS!.(196 arquivos) Foto de tudo, vídeo transando, fazendo duplo encarpado, chupeta e até canguru perneta ela faz) ACEITO PIX, PIC PAY. ENVIO EM WHATS E DISCORD.

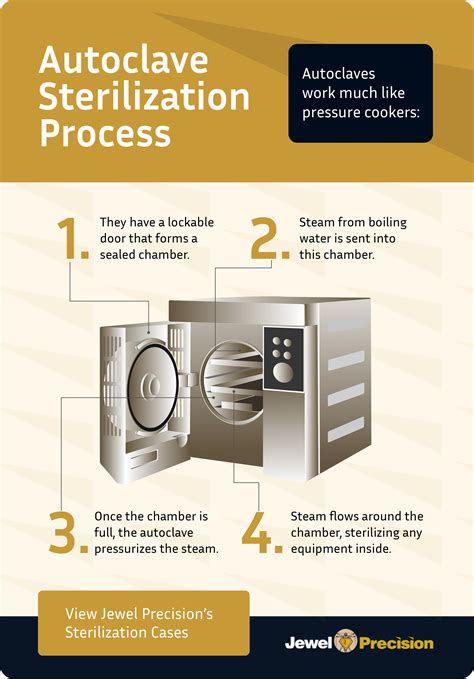

In healthcare, ensuring the sterility of medical instruments is crucial. Steam sterilization, or autoclaving, stands as a key defense against microbial contamination. Utilizing steam under pressure, this method .Material Requirements for Plastics Used in Medical Devices. Vinny R. Sastri, in Plastics in Medical Devices (Third Edition), 2022 4.2.1 Steam Sterilization. Steam sterilization (also called autoclaving) is conducted in an autoclave which is a container that can withstand high pressure and temperature. 11 The autoclave is filled with the products and devices that need to be . It goes without saying that not all loads can be run with the same sterilization cycle. This is why autoclaves are equipped to run various cycle types. Unfortunately, choosing a cycle type can be confusing, not to mention .Sterilization operation of the bioreactor is an essential link before carrying out the biological reaction experiment. If the sterilization operation is not in place, it is easy to contaminate the fermentation products during the operation of the bioreactor, resulting in greater losses. Therefore, it is very important to find the skills of sterilization. Next, we will briefly discuss the .

Heat sterilization is the most effective method of sterilization, where the elimination of microbes is achieved by the destruction of cell constituents and enzymes. It is done by two methods: Moist Heat Sterilization: It is one of the best methods of sterilization. Moist heat sterilization is done with the help of an instrument called an autoclave.

It is generally accepted that terminally sterilized injectable articles or critical devices purporting to be sterile, when processed in the autoclave, attain a 10 –6 microbial survivor probability, i.e., assurance of less than 1 chance in 1 million that viable microorganisms are present in the sterilized article or dosage form. With heat-stable articles, the approach often is to considerably .

As scale increases, autoclaves become impractical for sterilizing liquid medium. Typically, fermenters greater than 5 L in volume are sterilized in situ using live steam injection . When heat sterilization is scaled up to larger volumes, longer treatment times are needed to achieve the same sterilization result at the same holding temperature .

Explanation: Autoclave is an instrument that works on the principle of batch sterilization. It is used to kill germs which invade the fermentation media. The incubator provides optimum conditions for the growth of microorganisms. Laminar Air Flow (LAF) prevents the contamination of biological samples. Sterilization of a fermenter can be achieved through various techniques, including autoclaving, chemical treatments, filtration, or UV irradiation. Before the fermentation process begins, it is important to sterilize the fermenter and any .

An autoclave is a piece of equipment used in nearly all scientific fields and industries. It uses high-pressure steam to sterilize objects that can withstand the high temperatures. It turns hazardous waste into non-hazardous waste, and it’s responsible for the level of sterilization that’s able to be achieved today. Despite sterilization being mundane, it is a crucial step in the brewing process which cannot be skipped if you want your brew to succeed. In this guide, I’ll explain why sterilization is essential and share the best method for sterilizing your fermenter. . Fill your fermenter with the mixture of sterilizer and water as specified on the .

Quality steam is vital to a successful autoclave sterilization process. The steam used for sterilization should be composed of 97% steam (vapor) and 3% moisture (liquid water). This ratio is recommended for the most efficient heat transfer. When the steam moisture content is less than 3%, the steam is described as superheated (or dry).

The Hirayama HVE-50 autoclave sterilizer is a self-contained, . suited for the sterilizations of large fermenter vessels so is the perfect companion for fermenters like the Winpact fermenter. Hirayama HVE-50 autoclave sterilizer has a convenient agar sterilization mode for sterilizing agar and then automatically maintaining it at liquid .These conditions may be achieved in an autoclave in an atmosphere of saturated steam. Table 8. Wet-heat sterilization conditions. Temperature (°C) Time (min) Pressure (kPa) 121: 15: 103.4: 126: 10: 137.8: 134: 3: . Strategies for the bulk sterilization of fermentation media include in situ steam injection of a full charge of nonsterile . In 1876, Charles Chamberland developed the first pressure steam sterilizer or autoclave. In 1881, Robert Koch and his colleagues on the disinfection properties of steam and hot air marked the beginning of the science of disinfection and sterilization. . Sterilization of fermentation media or equipment is the first and most important process .

The source url Autoclave Sterilizer Machine stands as a cornerstone in ensuring effective and reliable sterilization in various industries and healthcare settings. This essential equipment, often used in laboratories, medical facilities, and research institutions, plays a pivotal role in eliminating harmful microorganisms and ensuring the .%PDF-1.6 %âãÏÓ 408 0 obj > endobj xref 408 69 0000000016 00000 n 0000002437 00000 n 0000002574 00000 n 0000002764 00000 n 0000002808 00000 n 0000003351 00000 n 0000003645 00000 n 0000004103 00000 n 0000004643 00000 n 0000005218 00000 n 0000005634 00000 n 0000005746 00000 n 0000006265 00000 n 0000006776 00000 n . Adhering to proper procedures, understanding compatible and incompatible materials, and ensuring regular autoclave validation are essential for the successful and safe use of autoclaves. With the knowledge gained from this guide, you are now equipped to utilize autoclaves effectively and contribute to the maintenance of a clean and sterile laboratory .

They may also be required in industrial applications where they become part of venting systems on fermenters, centrifuges, autoclaves, and freeze dryers. Filtration sterilization of liquids Membrane filters , in the form of discs, can be assembled into pressure-operated filter holders for syringe mounting and in-line use or vacuum filtration . A new continuous sterilization system was designed, constructed, started up, and qualified for media sterilization for secondary metabolite cultivations, bioconversions, and enzyme production. An existing Honeywell Total Distributed Control 3000-based control system was extended using redundant High performance Process Manager controllers for 98 I/O . Sterilization Process Controls. . If you are inspecting a contract sterilizer, Inspectional Objectives 2 through 5, described below, are applicable and must be performed. Inspectional Objective . Gravity displacement type autoclave. This is the common type of autoclave used in laboratories. In this type of autoclave, the steam is created inside the chamber via the heating unit, which then moves around the chamber for sterilization. This type of autoclave is comparatively cheaper than other types. Positive pressure displacement type (B-type)

Sterilization and Bioreactor Operation David Shonnard Department of Chemical Engineering Michigan Technological University . → 50,000 L fermenter requires 7x106to 7x107 L air/day → microorganism concentrations in air are about 1-10 / L air Methods for Air Sterilization at Inlet 1. Adiabatic compression, 220˚C for 30 secondsLast Updated on September 27, 2023 . If you’re new to the world of autoclaving (a.k.a. steam sterilization), you may have some burning questions about how lab autoclaves work and what the optimal temperature is for sterilization.In this article, we’ll provide you with the answers you’re looking for, as we delve into the significance of the temperature and other relevant information.As a leading Vertical Autoclave Manufacturer in Ahmedabad-Gujarat, Uma Pharmatech Machinery excels in providing top-quality sterilization solutions for various industries.Our unwavering commitment to quality and innovation positions us as a preferred choice in the market. As trusted manufacturers and suppliers of fermenters and autoclaves, we cater to .The Function of Autoclaves in Food and Beverage Sterilization and Sanitation Food safety is still a top priority for both consumers and industry experts. Sterilization is critical in providing the highest standards of food safety. This article goes into the complexities of food sterilization, the critical function of autoclaves, and how .

Autoclaves, the essential apparatus for sterilization, are in high demand across various industries, including hospitals, laboratories, and research centers. In Gujarat, India, several reputed manufacturers and suppliers are dedicated to producing top-quality autoclaves to meet the region’s sterilization needs.

when to question results of moisture meter

Acompanhantes de luxo na cidade de Ananindeua em PA. As mais lindas garotas de programas, confira as fotos e vídeos das perfeitas mulheres a procura de sexo. Se você .

autoclaves for fermenter sterilization|autoclave step by procedure